AUTOMATION AND SOFTWARE

We reduce the duration and costs of malfunctions

By sending its own technicians, but also by offering assistance by telephone,Bierre Automazioni can intervene immediately on the faulty machines, drastically reducing the downtimes and related costs of the same.

Our competences and possibilities of intervening and restoring the emergency situations range from working on and restoring software developed on old PLC Klockner Moeller ( PS22- PS24-PS316I), Siemens (S5-100/S5-115/ S5-135), Telemecanique (TSX), Rockwell Automation ( PLC 5- SLC 500), GE, up to the last generations of PLC and PC.

The knowledge of robotic plants management software allows our technicians to operate on Robot families of important brands such asFanuc, Kuka, Kawasaki and Motoman.

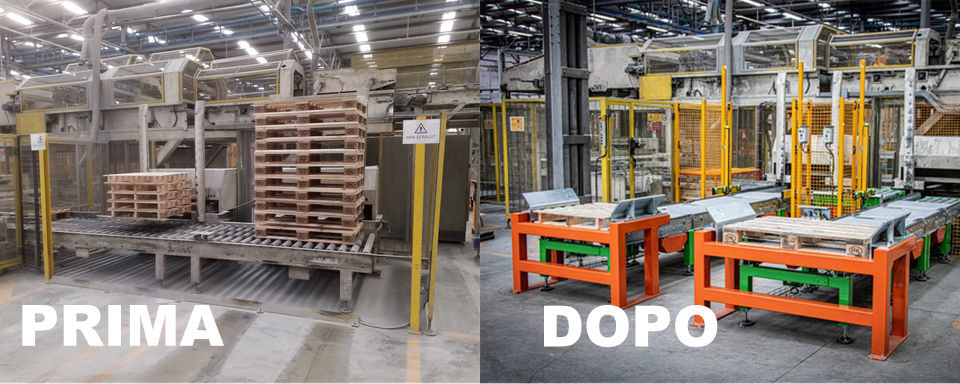

SACKS PALLETIZATION

Decades of specific experience

Particular attention should be paid to chapter “sacks palletization”. Over the years, within the structure of Bierre Automazioni , the persons and their capacity to provide qualified and competent electronic and mechanical assistance and maintenance to the customers operating in sacks palletization field evolved.

In particular Bierre Automazioni internally developed a specific service able to perform technical/commercial assessments and inspections on the machine and propose the necessary measures to be adopted, implementing them with expert staff.

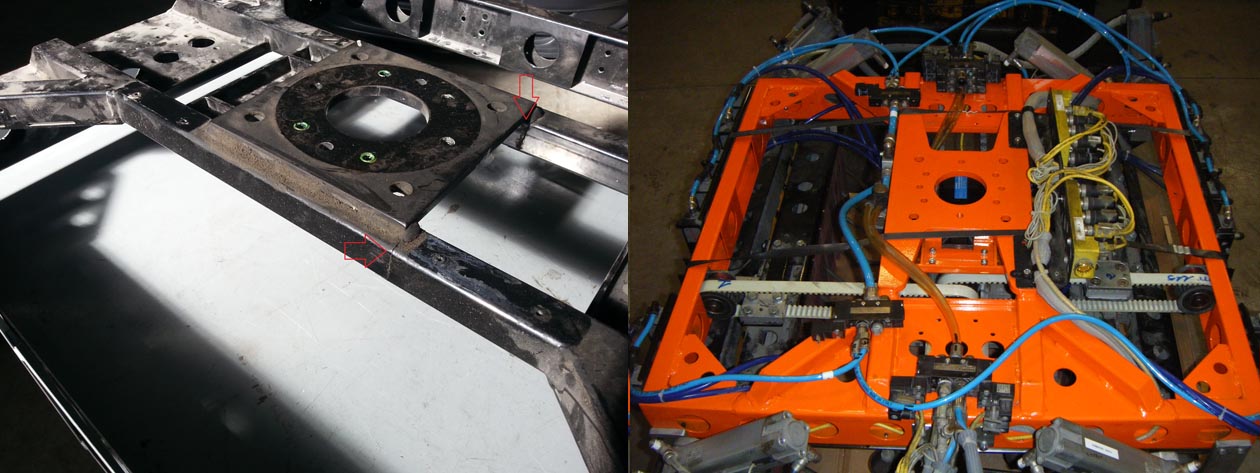

INDUSTRIAL PLANTS

At 360°, from A to Z

The growing demand from clients of outsourcing the routine maintenance operations, troubleshooting, interventions due to unexpected breakages, etc. pushed Bierre Automazioni to increase its competences for becoming a reliable partner in providing plant maintenance services.

Based on the nature of the works and on the specific demands of the customer,Bierre Automazioni is now able to manage service contracts for maintenance of various brands of equipment of plants/and or factories using customer’s employees or its own staff.