GYPROC, CASOLA (RA)

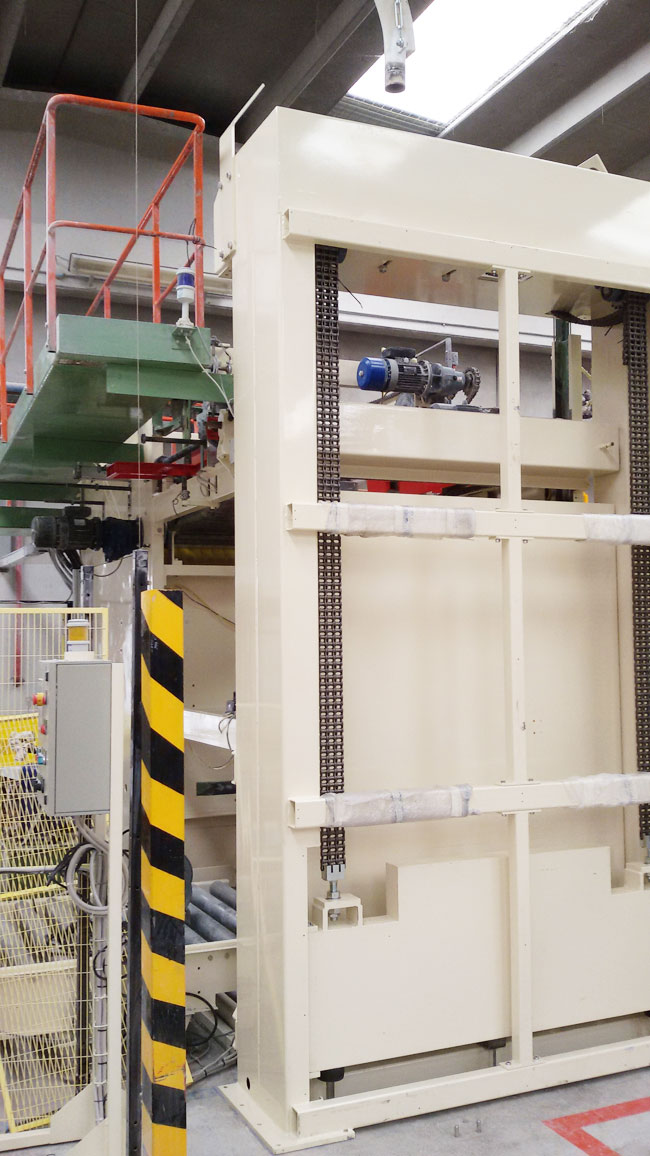

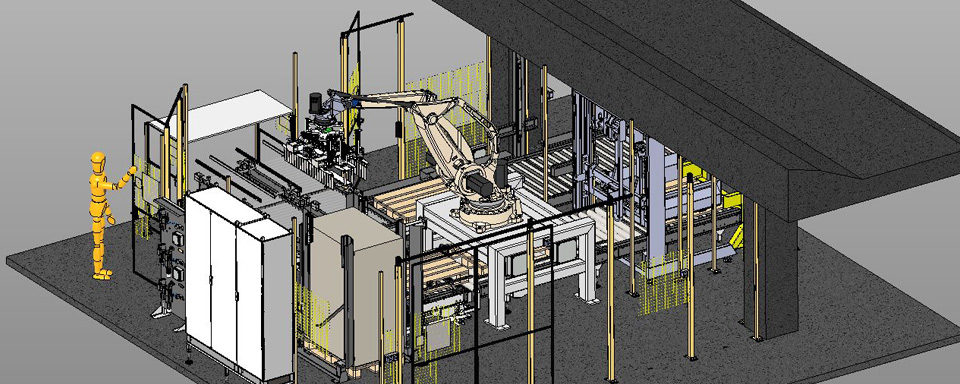

BIERRE AUTOMAZIONI IN CHARGE OF UPGRADING TO A ELECTROMECHANICAL LIFTING SYSTEM ON A SACK PALLETIZER, MOD. PAF/S

The costumer

Saint Gobain PPC Italia Spa, world leader in the building trade, produces and distributes new generation of materials for sustainable constructions, offering innovative solutions for energy efficiency and home comfort. During its 350 of activity, the Group has concretely demonstrated its ability to invent systems and products able to improve the quality of life.

Founded in France in 1665, today Saint-Gobain is one of the top 100 industrial groups in the world specialised in sustainable constructions, thanks to its partnerships with prestigious Universities and research Laboratories. Gyproc is the Saint-Gobain Group brand specialised in the production of dry construction systems (plasterboard) and plaster for the construction industry. Gyproc researches and develops avant-guard solutions defined by high standards of acoustic and thermic insulation, sustainability and superior fire protection.

The requirement

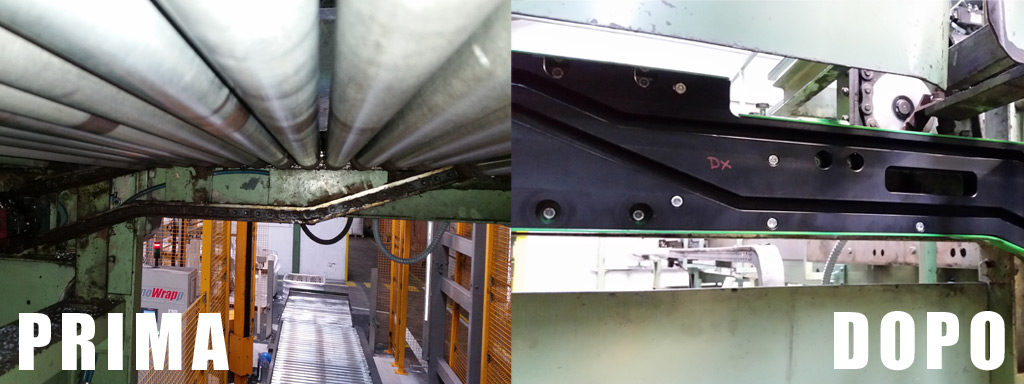

Hydraulic units powered by industrial oil, which are affected by the temperature variations of the environment, often cannot be adjusted and are therefore unreliable. Additionally, oil leaks are another reason why they are not considered environment friendly.

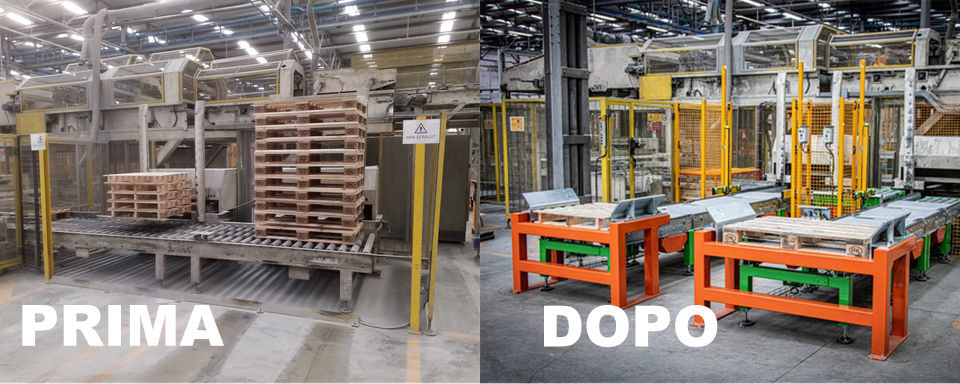

The 70% average reduction of power consumption measured in Kwh, the 12% reduction of active instantaneous electric power installed, the Inverter controlled main power, the reduction of the system noise, together with other technical and economic considerations, led Saint Gobain to put Bierre Automazione srl in charge of replacing the old hydraulic lifting system with a new electromechanical system.

Bierre Automazione intervention had to take place with no production/speed loss for the system and following exactly the schedule indicated by the Planning Department, in order to limit production losses due to downtime.

The solution adopted

THE RESULTS ACHIEVED

“The installation of the new system by Bierre Automazioni has considerably reduced both the irregularities due to the oil temperature variations in the hydraulic system and the noise, contributing to improve the efficiency of the machine, which despite its age is working perfectly again”

Re. Gyproc Maintenance – Casola plant (RA)

Contacts: Fabrizio Maestri (f.maestri@bierreautomazioni.com)