PROGEO MOLINI, GANACETO (MO)

BIERRE AUTOMAZIONI PROVIDES A NEW PERSPECTIVE FOR MANAGING EMPTY PLASTIC PALLETS.

The Customer

Progeo is one of the most important Italian agricultural cooperatives. On behalf of its associates, most of them located in Reggio Emilia provinces and part of them in Lombardia (Mantova-Cremona), Progeo gathers cereals, oilseeds and protein crops and processes them in its own industrial plants or sells them directly on the market .

Internal processing ensures the production of soft wheat flour for food industry and food for livestock farms. The grinding plant of Progeo Molini is located in Ganaceto (Mo), and operates in accordance with standards and principles provided by UNI ISO 9001-2008 quality certification.

The demand

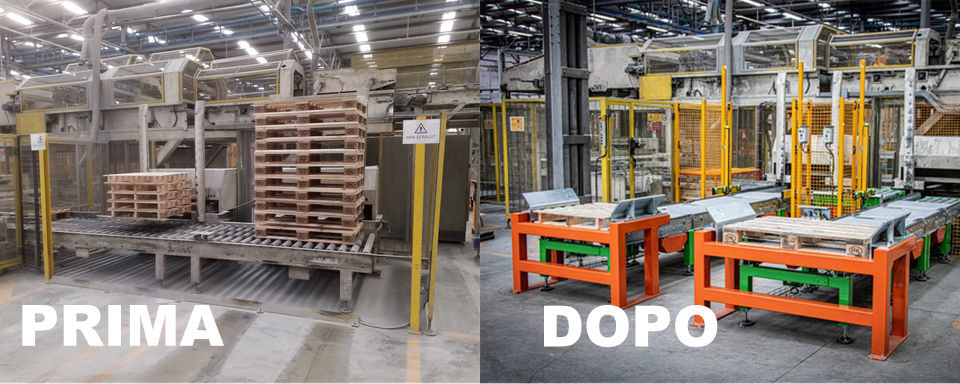

In order to meet the market demand of greater flexibility in “flour” storage and packaging, Progeo Molini decided to modify the existing plant (two sacks packaging lines designed to manage wooden pallets converging on a single palletizing robot) in order to palletize the packs on wood and plastic pallets at the same time, even with small product batches.

The intervention requested to Bierre Automazioni had to take place without any plant performance/speed loss. The new plant had to be designed so as to operate in area 22 (ATEX) in accordance with recent provisions.

The solution

-

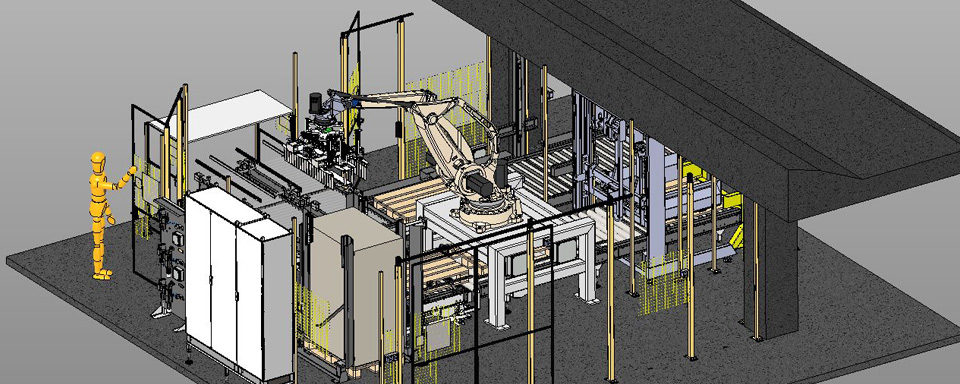

Bierre Automazioni proposed and provided Progeo Molini a series of new devices for managing the empty pallets infeed line, that provide a completely separated area dedicated to plastic pallets connecting to the existing palletizing line.

-

The new “area” was rendered independent using mechanical and electrical protection systems , a new pallet feeder and a coupling roller conveyor.

-

The new control panel, with manual commands features a data network with Profibus connection controlled inside the main electrical cabinet that allows the operators present on the plant to directly select empty wood or plastic pallets.

-

Thanks to an additional function, the entire system can be palletized on wood pallets and at the same time on plastic pallets on two different lines.

THE RESULTS

Roberto Barbieri

Packaging Line Production Manager Progeo SCA

Factory in Ganaceto (MO), Italy

“Thanks to the mechanical and electronic modifications made by Bierre Automazioni the versatility of the plant increased significantly (wood pallets and plastic pallets, small batches) improving at the same time productivity, significantly reducing waiting and management times when using plastic pallets .”

Gallery

Contacts: Fabrizio Maestri (f.maestri@bierreautomazioni.com)