VERSALIS SPA, RAGUSA (RG)

VERSALIS SPA, RAGUSA (RG): BIERRE AUTOMAZIONI CARRIES OUT A COMPLETE REVAMPING ON A BAGS PALLETIZER

The costumer

Versalis spa s a chemical society belonging to the Eni group, which operates on international level in the field of basic chemistry, plastic materials, rubbers and chemistry from renewable sources. With an overall production of 6 million tonnes and a total turnover of 6 billion Euros in 2013, Versalis commercializes chemical products through four business areas: Intermediates, Polyethylene, Styrenics, Elastomers.

The need

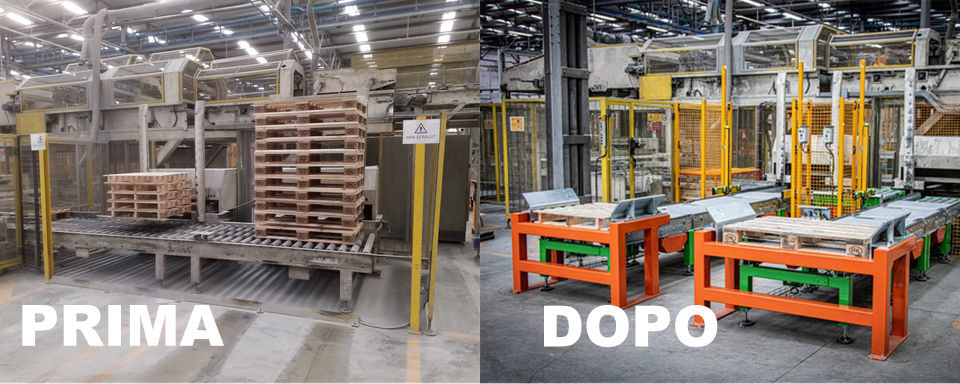

One of the Polyethylene production lines of the Ragusa (RG) plant used a bag palletizer not considered to be efficient due to a software, which didn’t meet the needs of the nowadays production. The principal problem was that of the recurring stops and of the difficulty that the operators and technicians found to identify the origin of the malfunctions.

Economical and technical evaluations leaded Versalis spa to the decision of completely replacing the operating software with a new one realized from the beginning whose characteristics could meet the plant’s production necessities.

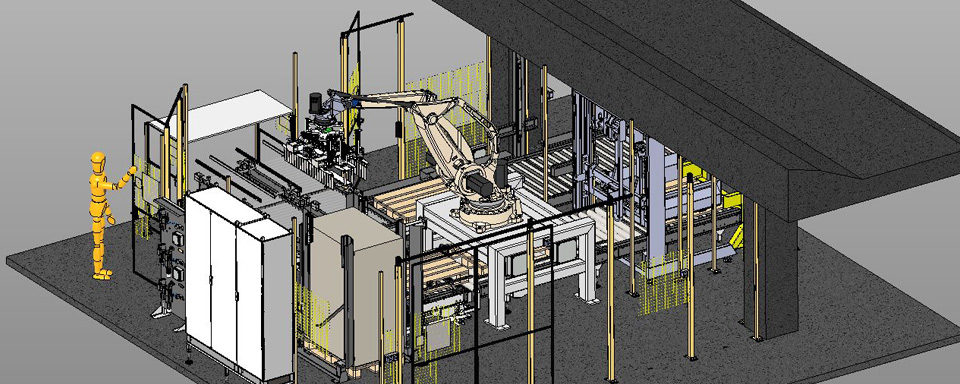

The intervention of Bierre Automazioni was supposed to avoid any loss of efficiency/speed of the plant and it should have respected the schedule fixed by the Planning office in order to limit the loss of production originated by the plant stoppage.

The solution

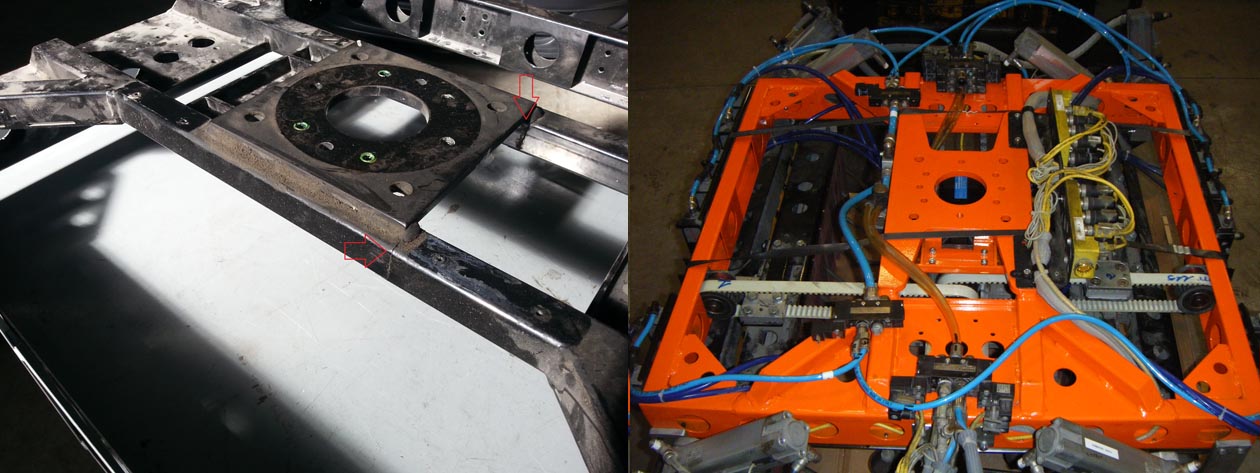

- Bierre Automazioni suggested and supplied to Versalis spa a turnkey full package, including a new software realized for Siemens S7 PLC series 300 and the following production tests in plants carried out by our software engineers.

- The new software has completely replaced the precedent and it has been created in order to be more user-friendly for Versalis spa operators and technicians as it facilitates the trouble-shooting activities in case of arrest.

ACHIEVEMENTS

VERSALIS SPA Maintenance Department- Ragusa (RG) Plant

“Thanks to the software modification realized by Bierre Automazioni, the plant stoppages considerably reduced and above all, when this kind of problem occurs, it is easier to find out the reasons that caused the arrest, contributing to reach a higher efficiency of the machine which, though dated, performs again in a perfectly efficient way.”

Gallery

Contacts: Fabrizio Maestri (f.maestri@bierreautomazioni.com)